Removes all LED modules that fall outside of any letter or object.

This is a rare situation, and sometimes you can't see any "stray" modules, but a couple of ways you can tell if you have them:

- Your stats show more modules than what you're seeing in the layout.

- Your layout size is very large relative to your actual design.

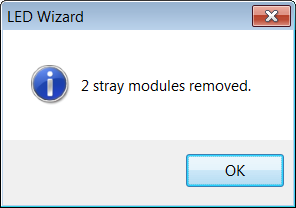

When you run this function, a dialog box will confirm as follows:

LED Wizard 8 Documentation

LED Wizard 8 Documentation

LED Wizard 8 Documentation

LED Wizard 8 Documentation